Plastic Recycling Codes and What they Mean

What’s that numbered recycling symbol mean on your water bottle? That’s what you call a “plastic recycling code”. Mostly all bottles, including glass items, have this numbered symbol. In this article, we’ll explain the purpose of these symbols and what each number means.

What is the purpose of recycling codes on plastics?

When you bring a bottle to a local recycling center at the grocery store, what’s the first thing you do? Decide whether or not the bottle goes into the plastic or glass machine. It’s the same concept for recyclers, but with more detail. Recyclers like us need to know the exact compound the recyclable is to know how to repurpose it or break it down.

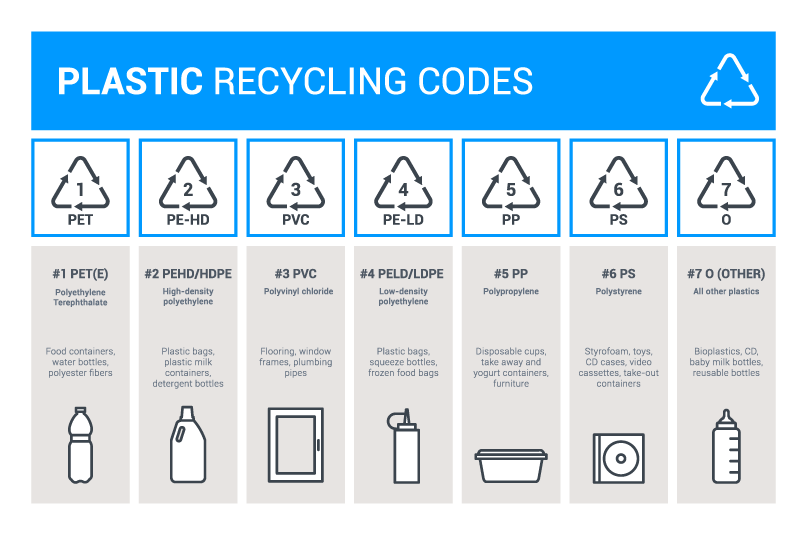

There are 7 total recycling codes for plastics, and generally, we can use all 7.

What does each code mean?

The seven recycling codes include:

Each of these refer to nonbiodegradable plastics that don’t break down in the environment. Thankfully, these plastics can generally be used with our machines.

Recycling Code 1: Polyethylene terephthalate (PETE or PET)

Recycling code 1 refers to Polyethylene terephthalate (PETE or PET) plastics. This is most likely the most common recycling code you’ve seen, particularly because most water bottle manufacturing companies have favored the cost effectiveness and durability of PETE to glass since the 70s. Thankfully, PET doesn’t leak BPA or phthalate toxins, but PET does emit a hundred times toxic environmental emissions when burned down.

Uses: Plastic water bottles, clothing, and glass resins.

Recycled into: Furniture, paneling, containers, blankets, straps, clothing & accessories.

Recycling Code 2: High Density Polyethylene (HDPE)

Recycling code 2 refers to High Density Polyethylene, or HDPE. HDPE has so many uses that it has become one of the top type of plastics exported globally. No surprise that the global HDPE market reaches a volume of around 2 million tons (around 15 lbs per person) annually. Of this weight, only around 470,000 tons (21%) gets recycled annually. Thankfully, HDPE doesn’t emit toxic fumes in landfills–but it does tend to be so lightweight that it will blow out of landfills–disturbing oceans, forests, and the flora within each.

Uses: Housewrap, 3D printer filament, bottles, clothing production, food containers, jerrycans, plastic shopping bags, and other construction materials.

Recycled into: fences, lumber compounds, floor tiles, drainage pipes, tables, benches, and even doghouses.

Recycling Code 3: Polyvinyl Chloride (PVC)

Polyvinyl chloride is symbolized by recycling code #3. PVC is inexpensive, versatile, and fairly weather resistant. The issue is that PVC contains chlorine, a chemical that releases toxins during the manufacturing (and burning) process. You’ve probably heard of PVC from its applications in piping and tubing before, but did you know about all the other applications?

Uses: Piping, siding, windows, wire insulation, packaging, bottles and containers.

Recycled into: Construction panels, decks, flooring, mats, carpeting, road gutters, speed bumps, and more.

Recycling Code 4: Low Density Polyethylene (LDPE)

Low density polyethylene (LDPE) is symbolized with recycling code 4. LDPE is the low density sibling of HDPE, which means it’s softer, more flexible, and less temperature resistant. You can tell the difference between LDPE and HDPE by crinkling it–if the material softly “swishes” like a tree blowing then it’s LDPE. HDPE sounds more “crinkly” when handled, like dried up leaves.

Uses: Furniture, squeezable bottles, frozen food packaging, shopping bags, clothing & accessories, like totes.

Recycled into: Floor tiles, paneling, lumber compounds, trash cans, trash liners, and garbage bins.

Recycling Code 5: Polypropylene (PP)

Polypropylene (PP) is symbolized by recycling code 5. PP has a high melting point and is used in applications that require high heat. However, PP leaks and heat increases exposure to microplastics. In fact, it’s estimated that thousands to millions of infants are exposed to microplastic particles a day from warming polypropylene infant bottles. Most PP should be repurposed for non consumable products, like for construction, but despite its high production, only 1% gets recycled.

Uses: Kettles, flip top on reusable water bottles and tic tac containers, pipettes, laboratory vials, plastic chairs, clothing, concrete additive, drywall reinforcement, plastic biocontainer drums, and even some currencies.

Recycled into: Concrete additives, bins, cable insulators, battery cables, pallets, dishware.

Recycling Code 6: Polystyrene (PS)

Ah yes, infamous Polystyrene (PS), also known as Styrofoam, or Expanded Polystyrene (EPS), is signified by recycling code 6. This plastic is significantly more lightweight and adaptable to the preceding plastics, but extremely harmful when disturbed or heated. Because of its simple molecular structure, PS interacts with the environment and our biochemistry in unpredictable ways.

The EPA once took a random sample of and found that 100% of the sample had Polystyrene toxins in their blood. PS takes around 500 years to start decomposing and has been classified as carcinogenic. Despite that, polystyrene continues to be manufactured and used as a common plastic.

Uses: Disposable plates, cups, trays, cartons, carry out containers (DO NOT put a styrofoam container in the microwave), prescription bottles, and DVD cases.

Recycled into: Insulation, light switch panels, air vents, rulers, and other HVAC/R components.

Recycling Code 7: OTHER

Other plastics that don’t fit into other recycling codes get classified as “OTHER”, or recycling code 7. These plastics are anything that doesn’t fit into the preceding plastics, which could be PLA (polylactic acid), PETG (Polyethylene terephthalate glycol), and Polycarbonates (a known hormone disruptor).

Common Uses: 3D printing filament, gallon water bottles, sunglasses, DVD cases, phone cases, signs and displays, certain food containers, and nylon clothing.

Recycled into: plastic lumber and other custom 3D printed material and products.

How we use recyclable plastics

We are converting plastics into construction uses. Most plastics mentioned above can be converted into 3D printer filament, which is used by our 3D printers to create environmentally friendly home products and construction material.

By using plastics in our 3D printing process, we remove them from the environment and repurpose them for safe consumption in our homes. For example, polystyrene that may be repurposed as potentially harmful disposable food containers are instead being repurposed in home wall insulation.

What you can do do with your unused plastics

There’s most likely an unused piece of plastic not too far from you. Truth is, we’re surrounded every day, even though we don’t often think about it. If you are looking at a piece of plastic that you can recycle, we recommend thinking twice before throwing it away. You can do this by visiting your local recycling center.